Technical capability’s introduction

01 Automotive parts field

Internal combustion vehicle

EV/FCV vehicle

02 Other industries and parts field

Industrial Equipment

Components that support industrial technology around the world

Medical Devices

Small parts that support lives in the medical field

Telecommunications Equipment

Components that support infrastructure without interruption

Others

Invisible parts that support our lives

Case Study

Car air conditioner compressor parts

Developing original special cutting tools

The customer had initially planned to manufacture the parts in-house at their local factory (in France) but gave up due to high technical hurdles. While no other manufacturers capable of producing the product could be found in Japan, Matsumoto Kosan developed an original special blade tool after much trial and error and succeeded in starting mass production.

| Monthly production volume | 250,000 pieces |

|---|---|

| Material | C3604 |

Automobile and transmission parts

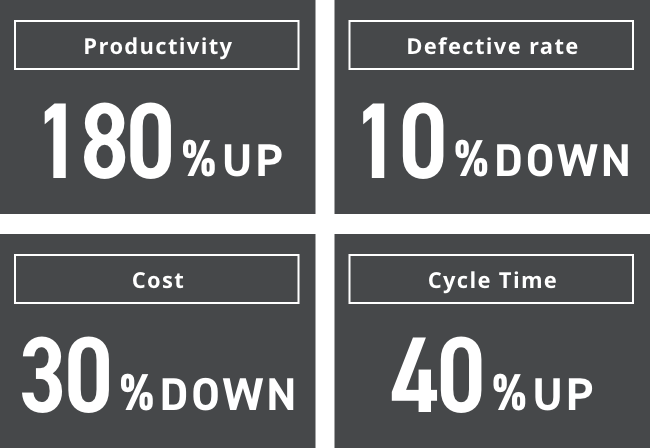

Consolidating multiple processes into one CNC lathe

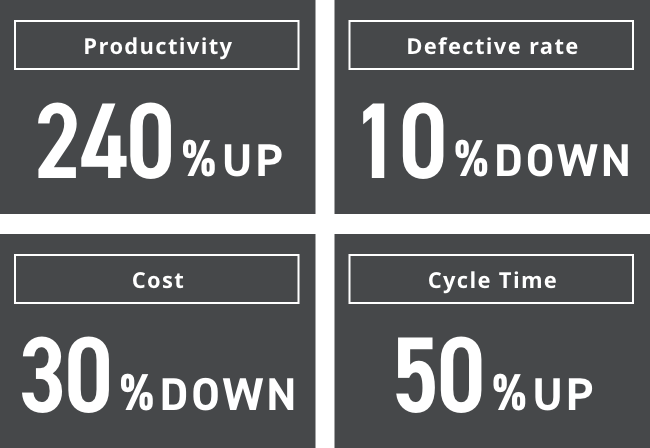

In a situation where they had to rush to supply, there were frequent defects in in-house production, and the enormous equipment costs were also a source of concern for customers. Matsumoto Kosan’s plan is to combine the four processes that previously existed on the production line (blank creation, honing, deburring, and finishing) into a single processing machine. While maintaining an inner diameter of φ7.49+0.012/+0.004, we have achieved low capital investment and low cost.

| Automobile parts/shock absorbers. | 180,000 pieces |

|---|---|

| Material | A2014 |

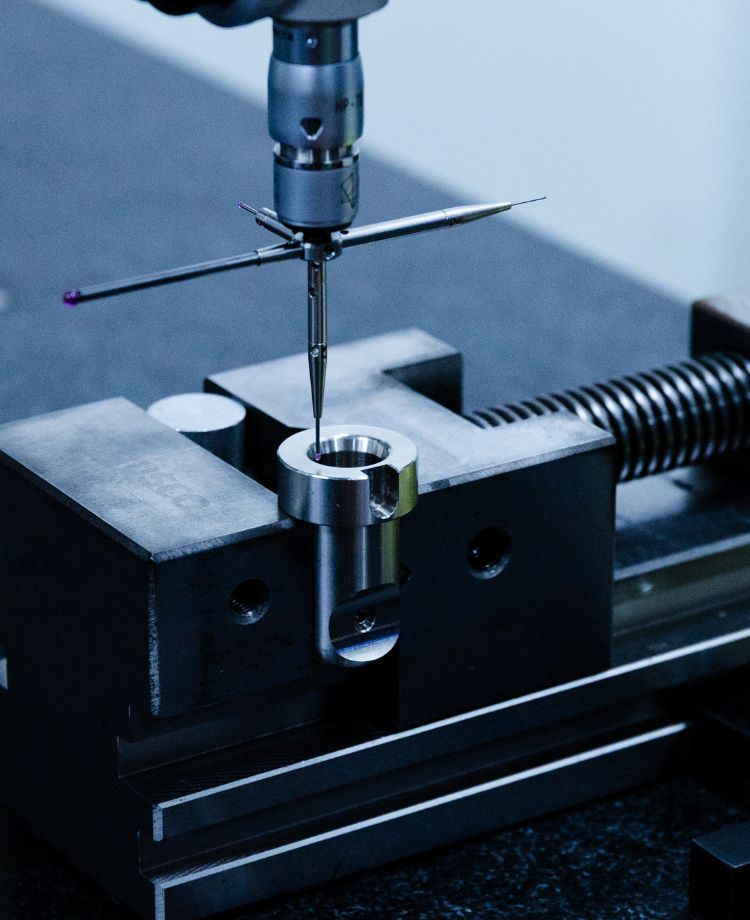

Automobile parts/shock absorbers.

Consolidating multiple processes into one CNC lathe

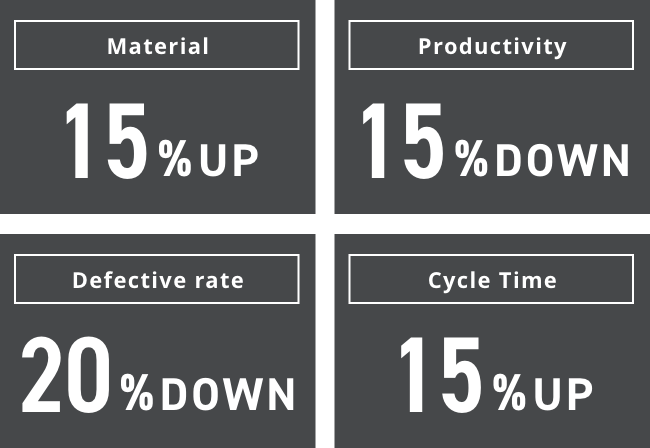

In the past, chamfering the inside of a long, narrow hole required a total of four processes: NC lathe, machining center, internal diameter burnishing (manual work), and horizontal hole internal diameter deburring (manual work). However, Matsumoto Kosan has succeeded in consolidating these four processes into one processing machine and completing the process without post-processing (honing and deburring). A significant improvement in yield was also achieved.

| Monthly production volume | 5,000 pieces |

|---|---|

| Material | S45C |

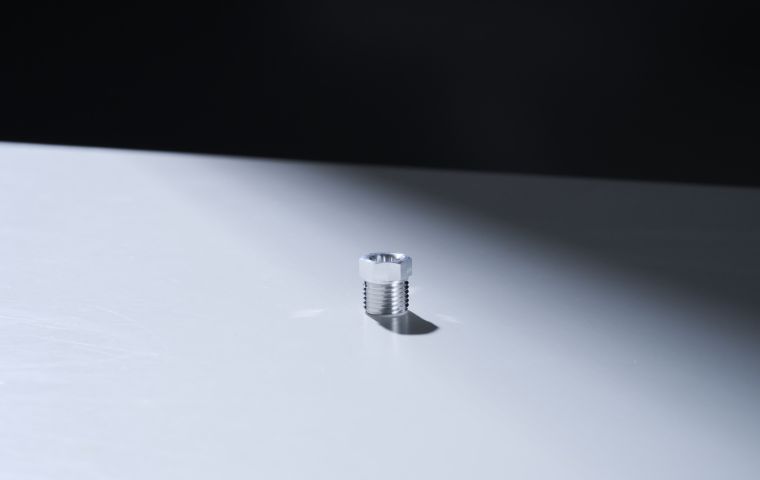

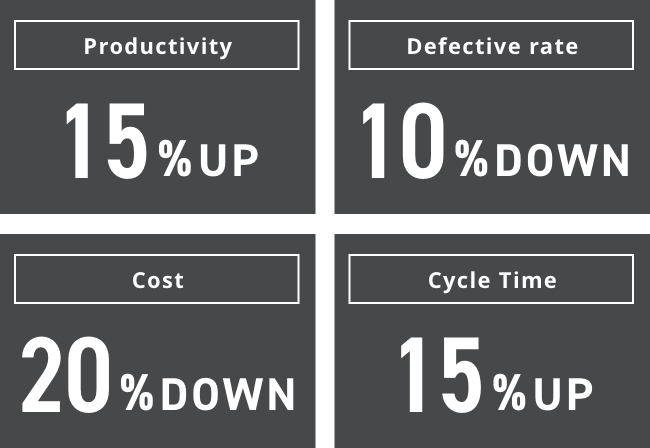

Fire doors and fireproof lock parts

Cost reduction by changing the manufacturing method to cutting process

The method of post-processing brass die-cast blanks has been replaced with cutting process from bar material. Furthermore, by eliminating the post-processing step and completing the process on a single processing machine, they also succeeded in reducing mold costs, which were expected to be high. It is the case that the order was taken due to the expectation of reducing costs while maintaining quality.

| Monthly production volume | 1,000 pieces |

|---|---|

| Material | C3604 |