Streamlined Production with One-Piece Flow

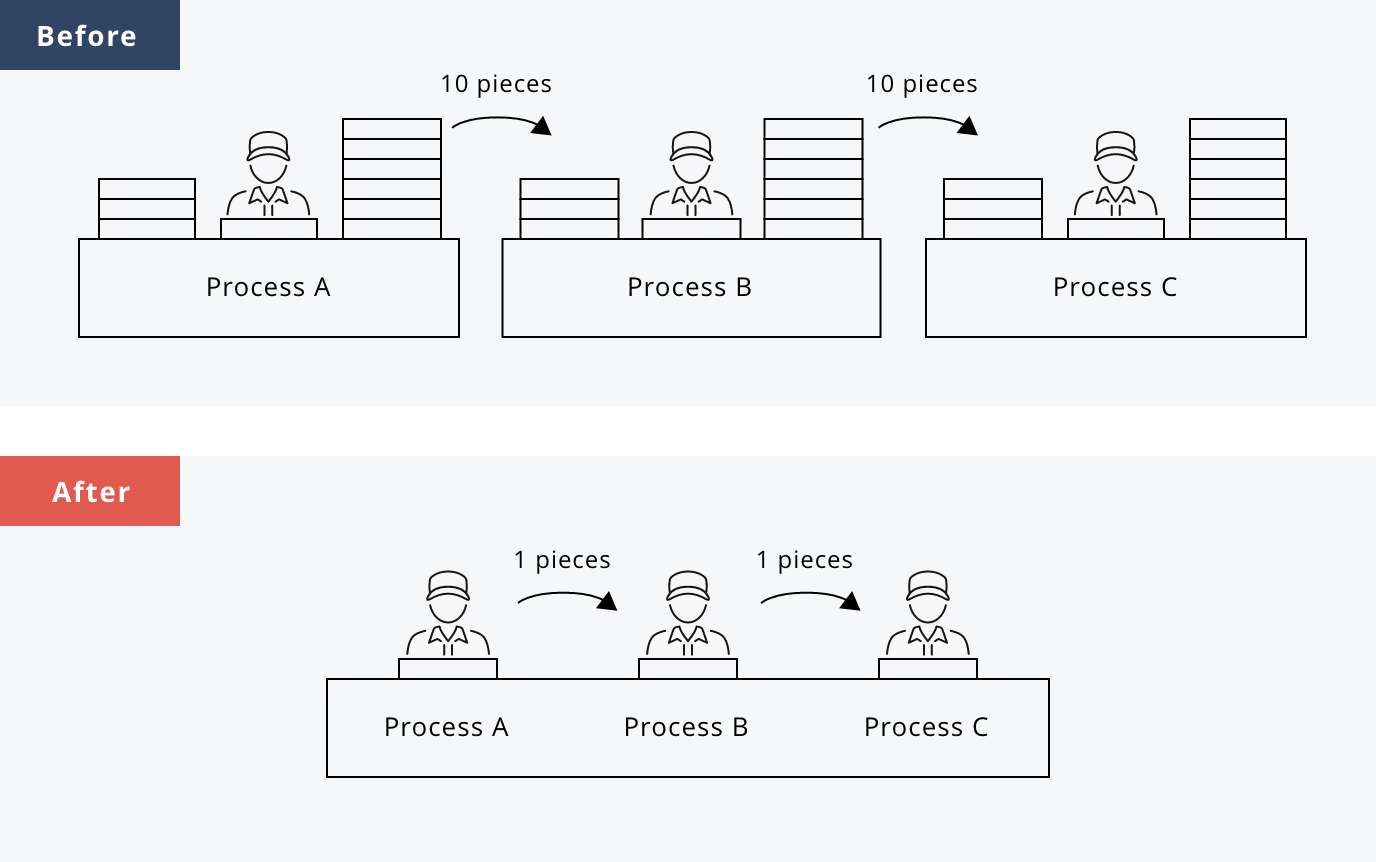

Matsumoto Kosan Thailand has adopted “One-piece flow production,” one of the Toyota Production Systems, to realize “improved quality” and “improved productivity” in the production process.

We will reduce the amount of work that occurs between processes as in the past and provide a one-stop service from manufacturing to inspection and packaging.

This allows each process to proceed smoothly, significantly shortening the lead time until the product is completed. In addition, because there is no work in progress between processes, any defects can be discovered immediately, preventing the occurrence of large amounts of defects.

One piece flow (see Toyota Production System)

This allows each process to proceed smoothly, significantly shortening the lead time until the product is completed. In addition, because there is no work in progress between processes, any defects can be discovered immediately, preventing the occurrence of large amounts of defects.