Masterful craftsmanship and quality control that build trust

Building global trust through “precision” and “sincerity.” Matsumoto Kosan’s craftsmanship and commitment to quality.

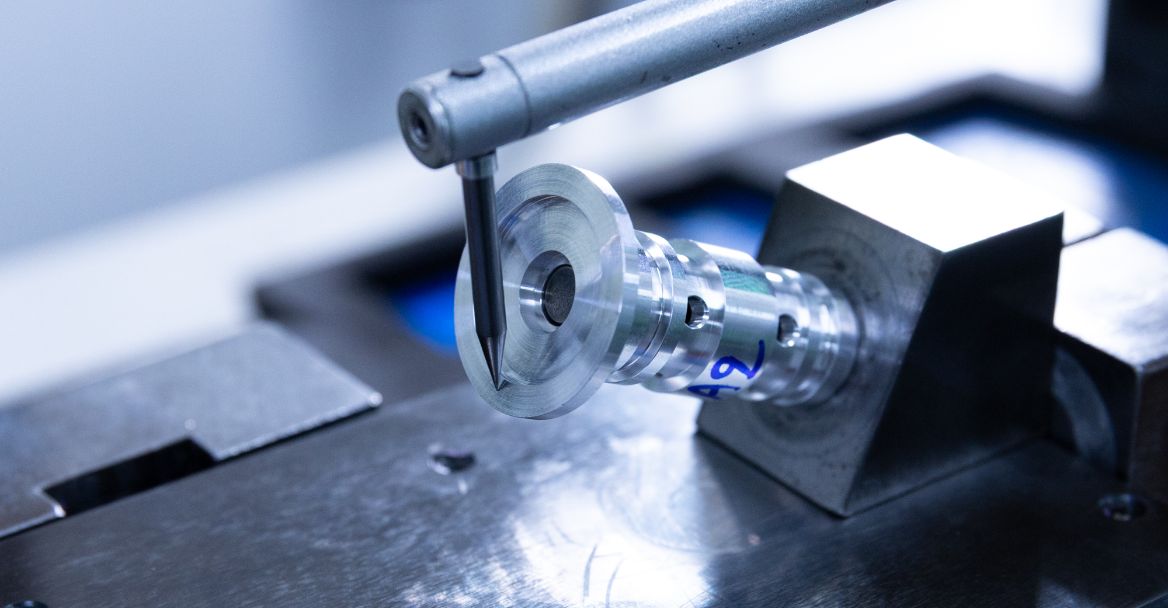

Pursuing invisible precision

Matsumoto Kosan’s craftsmanship is supported by the delicate processing techniques of our skilled technicians and our own special cutting tools.

Our flexible system allows us to handle everything from prototypes to mass production, and the ability to “cut out” anything precisely from a single item to large lots, make invisible precision of commitment become shapes.

Processing techniques by veteran technicians

In-house development of special cutting tools

Development capabilities that support everything from the prototype stage

Ability to “carve out” anything from small lots to mass production

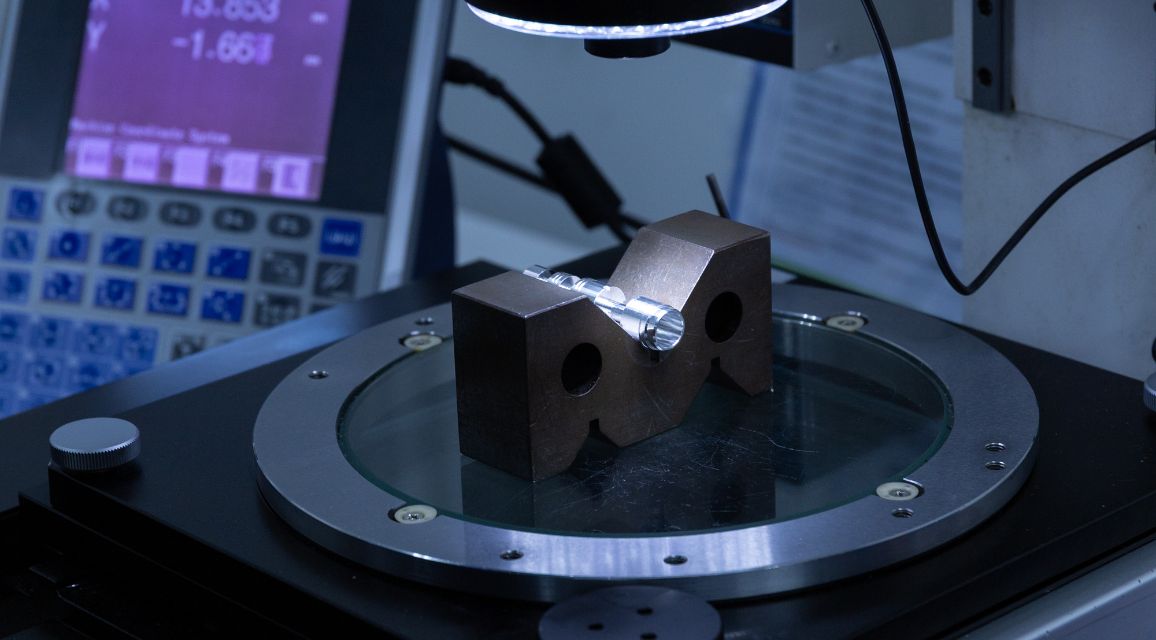

Measurement technology that achieves an error of 0.1μm

Matsumoto Kosan’s quality assurance system makes full use of cutting-edge inspection technology, including high-precision measuring equipment that enables measurements with an error level of 0.1μm, and 100% appearance inspection that combines visual inspection with AI image recognition. We strive for zero defects even amid high-mix mass production, and by making the inspection process in-house compliant with ISO and IATF visible, we always achieve consistent quality.

Quality Policy and Continual Improvement

Matsumoto Kosan’s quality assurance system makes full use of cutting-edge inspection technology, including high-precision measuring equipment that enables measurements with an error level of 0.1μm, and 100% appearance inspection that combines visual inspection with AI image recognition. We strive for zero defects even amid high-mix mass production, and by making the inspection process in-house compliant with ISO and IATF visible, we always achieve consistent quality.

Measuring equipment list

| Equipment name | Manufacturer name | Model | Number of units | Remarks |

|---|---|---|---|---|

| Measuring microscope | Mitutoyo | MF-A1010C | 10 | |

| Two-dimensional data processing device | Mitutoyo | QM Data-200 | 10 | |

| Dial Gauges | Mitutoyo | ID-H0560 | 14 | |

| Integrated surface roughness and contour measurement machine | Tokyo Precision | SURFCOMNEX130DX | 2 | Roughness, shape, and contour analysis possible with a measurement magnification of 2 million times |

| Roundness measuring machine | Tokyo Precision | RONDCOM54DX NEX300DX-11 |

2 | Roundness, cylindricity, concentricity, flatness, squareness |

| Automatic visual inspection machine | - | - | 4 | Measure circle diameter to the nearest 0.2 microns |

| Electric signal type air micro | Tokyo Precision | E-DT-AH-0350 | 24 | |

| Three-dimensional measuring machine | Tokyo Precision | Duramax | 1 | Measure circle diameter to the nearest 0.2 microns |

Scroll

“Surface roughness and contour shape measuring instrument” with high accuracy, resolution of 0.0005 microns, and dial gauge resolution of 24000:1, “Cylindrical Shape Measuring Machine” that can measure not only roundness and cylindricity but also axiality, flatness, and squareness, and “Measuring Microscope” that can measure points that cannot be measured by micrometers, etc.

Main processing equipment

A20

| Manufacturer name | Citizen Machinery |

|---|---|

| Model | A20 |

| Maximum machining diameter | 20 |

| Number of units | 24 |

| Product Description | High-speed, high-precision machining of complex shaped parts |

L20

| Manufacturer name | Citizen Machinery |

|---|---|

| Model | L20 |

| Maximum machining diameter | 20 |

| Number of units | 36 |

| Product Description | High-speed, high-precision machining of complex shaped parts |

L12/16

| Manufacturer name | Citizen Machinery |

|---|---|

| Model | L12/16 |

| Maximum machining diameter | 12 |

| Number of units | 18 |

| Product Description | High-speed, high-precision machining of complex shaped parts |

BNJ-51SY6

| Manufacturer name | Citizen Machinery |

|---|---|

| Model | BNJ-51SY6 |

| Maximum machining diameter | 51 |

| Number of units | 2 |

| Product Description | It can handle materials up to Φ51, and has a rotating tool on the back side, so it can also handle complex shapes. |

BNE-51SY6

| Manufacturer name | Citizen Machinery |

|---|---|

| Model | BNE-51SY6 |

| Maximum machining diameter | 51 |

| Number of units | 4 |

| Product Description | Equipped with two turrets of the same capacity, it achieves time-saving and high-precision machining by distributing the processes. |

R450X2

| Manufacturer name | Brother |

|---|---|

| Model | R450X2 |

| Maximum machining diameter | 20 |

| Number of units | 24 |

| Product Description | High-speed, high-precision machining of complex shaped parts |

MPC-450

| Manufacturer name | Citizen Machinery |

|---|---|

| Model | MPC-450 |

| Maximum machining diameter | 20 |

| Number of units | 24 |

| Product Description | High-speed, high-precision machining of complex shaped parts |